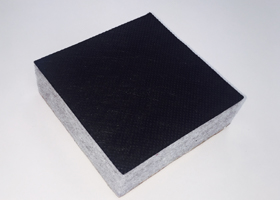

Sound insulation

Our original QonPET soundproofing material comprehensively improves sound insulation performance, durability, workability and cost performance.

We began the development of the material after receiving a request from customers to suppress the engine noise on construction machinery out of consideration for the people nearby. We conducted research into high performance materials and structures that could replace the urethane and glass wool used previously. The result was the birth of the “QonPET”® high performance sound absorbing material made from non-woven polyester fabric. We searched for the optimal level of fiber density and the product was finally completed after the evaluation of dozens of prototypes. The durability has been improved and also the weather resistance is improved from that of urethane and the workability is improved from that of glass wool.

- We focused on polyester non-woven fabric out of the many different materials possible

- As we used raw materials that have superior sound insulation properties, workability, processing properties, weather resistance and water resistance, this led to the development of a high performance and long-lasting product

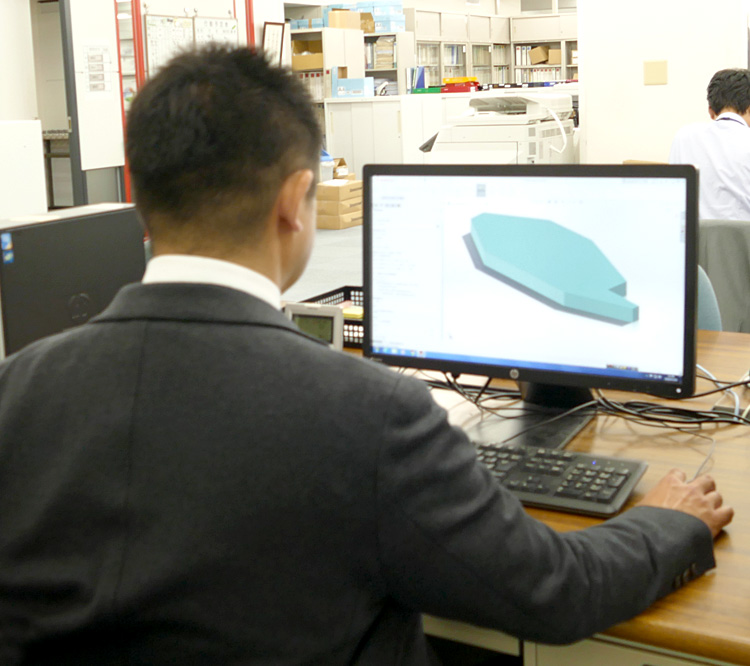

Vibration isolation

Success in the protection of lightweight precision instruments with an original rubber vibration isolator

A certain railroad company had been attempting to perform damping for a highly sensitive sensor by installing cushion rubber, but had not been able to suppress the vibration. By utilizing our sophisticated rubber technology in our research and development, we were able to obtain a sufficient effect with an original rubber vibration isolator for light loads that we developed ourselves. We succeeded in preventing the damage to the sensor instrument.

- Vibration isolation technology developed over many years

- Reassuring environmental measures and support systems

- Customization for a wide variety of applications with multiproduct production

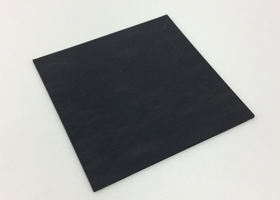

Damping

A solution to issues in the three areas of noise, vibration and costs with an original damper

We proposed original dampers to solve the problem of noise and vibration in the engine room of an automobile. This was selected after comparing multiple manufacturers, for high level damping due to the high specific gravity and excellent workability. In addition to the customers being pleased with the high damping effect, we were also able to promote the appeal of its cost merits.

- The material is thin and has excellent flexibility, so it fits closely to parts that have uneven surfaces

- It has a high specific gravity and can be used for a wide range of frequencies (vibrations)

- Its cost is a large merit

Dustproofing

The proposal of filters that effectively catch dust at the PM2.5 level

Filters are used for various roles depending on the size of the dust particles to be removed. We choose from a large range of materials manufacturers to propose the materials and profile necessary to fit the order from the customer within the limitations of the cost.

- We select the material for the filter depending on the dust to be removed

- We choose from a wide range of materials manufacturers to propose the materials and profile to fit the cost target

Waterproofing

A solution found by changing the materials on equipment that did not sufficiently stop water

We received an inquiry from a customer about the waterproofing of an electrical transmission box that was placed outdoors. We therefore interviewed the customer about the installation location and the shape of the fit. We considered what level of waterproofing would be necessary for the sealing material in the environment of the installation and selected materials. Before making the request, the customer had been using low compression urethane sponge material. However, on consideration of the environment for use outdoors, we managed to stop the water with a high compression EPDM rubber foam material with closed cell foam.

- We proposed materials suitable for the installation environment

- We considered many different materials and selected EPDM rubber foam materials